PLC & HMI Programming and Repair

PLC & HMI programming and repair involve designing, troubleshooting, and maintaining the control systems that automate industrial machinery and processes. A PLC (Programmable Logic Controller) is a rugged computer used to control machines by processing input signals and sending commands to outputs, while an HMI (Human-Machine Interface) provides a user-friendly graphical interface for operators to monitor and interact with the system.

Programming a PLC requires developing logic sequences using specialized software, often with ladder logic or function block diagrams, to ensure the machinery operates as intended. This includes configuring inputs (like sensors and switches), outputs (motors, valves), timers, counters, and communication protocols. HMI programming involves creating intuitive screens that display system status, alarms, and allow operator control, often using drag-and-drop tools within the HMI software.

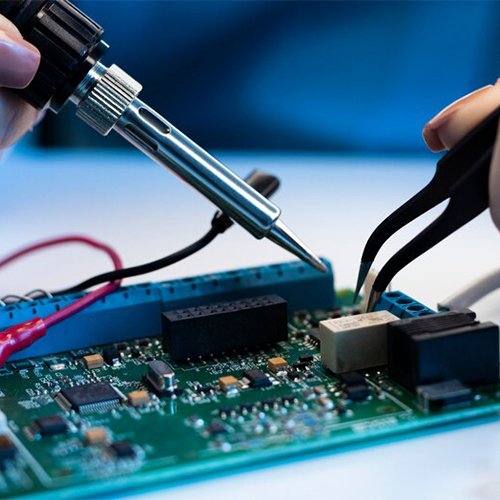

Repairing PLCs and HMIs usually starts with diagnosing hardware faults such as damaged input/output modules, power supplies, or communication failures, as well as software issues like corrupted programs or configuration errors. Troubleshooting often requires connecting diagnostic tools or software to monitor system behavior, checking wiring and connections, and restoring or rewriting programs when needed.